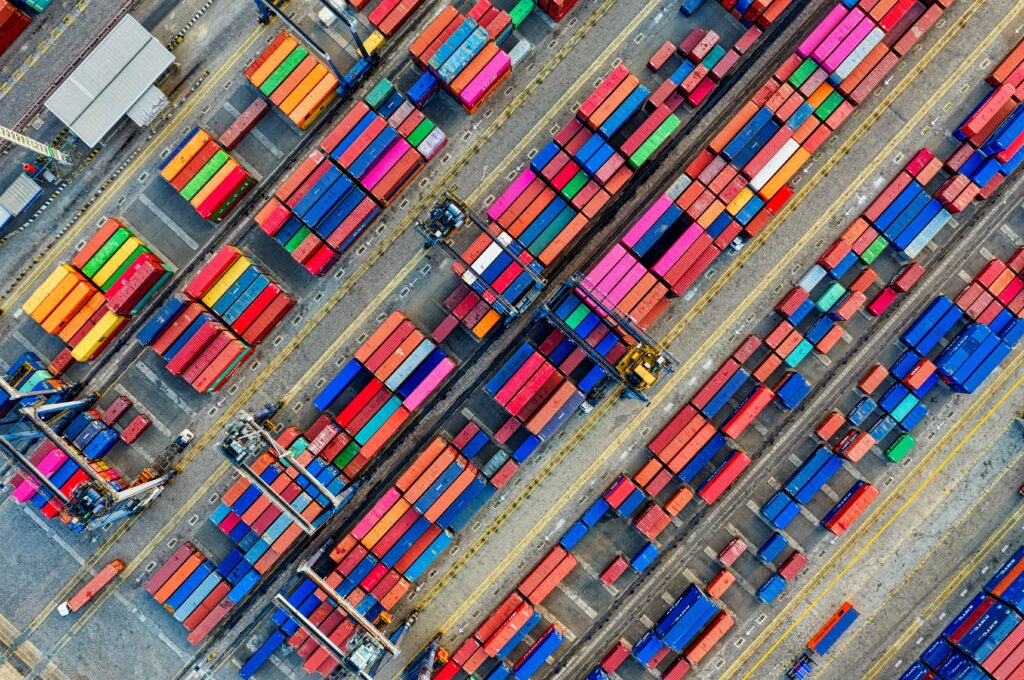

Digital Catapult, the UK authority on advanced digital technology, has partnered with five leading technology companies and six pioneering SMEs to solve critical supply chain challenges facing small-to-medium sized manufacturers across the country. As part of the Made Smarter Innovation | Digital Supply Chain Hub, the initiative will fund and facilitate the development of pioneering solutions to remedy significant industrial challenges, with a view to driving economic growth and advancing the UK’s manufacturing sector.

The competition will fund the development of advanced digital solutions with up to £100,000 for each tech company to deploy their solutions into the supporting manufacturer’s businesses who will receive £25,000 to bolster this activity.

To maintain the UK’s position as number nine in the world in terms of manufacturing output, the challenges identified in this programme will be key to ensuring that manufacturers can look to innovation as a means of improving efficiency and achieving sustainable growth. These challenges include:

- improving compliance and reducing the administrative burden on SMEs in the FMCG industry through the use of digital and paperless systems, supporting export growth through improved compliance to export regulations.

- reducing waste in the textile industry through the use of digital infrastructure to explore the diversion of waste to secondary markets.

- providing visibility of inventory levels and/or delays in supply to enable better planning and prioritising by the SME manufacturer in the automotive industry.

- understanding the true costs of purchasing materials so the SME manufacturers can make better decisions around sourcing and reduce their overall input costs.

The project comes as a recent survey from Make UK and BDO highlighted the challenges currently facing UK manufacturers, with output growth for 2023 expected to be at -0.3%. Supply chain pressures were outlined as a key challenge for medium-sized firms, with continued disruption and increased costs at home and abroad stalling business growth.

The programme will help to address these challenges outlined by manufacturers by developing solutions to real-world industrial challenges in the manufacturing space, and will look to leverage emerging technologies that can be deployed at scale, to sharpen the UK’s manufacturing edge. This includes solving industrial challenges by utilising artificial intelligence (AI), machine learning, internet of things (IoT) technologies, and blockchain.

‘With around 250,000 SME manufacturers in the UK, it’s important that the work that we do as part of the Digital Supply Chain Hub backs these organisations as we introduce advanced digital tools to the supply chain. We’re excited to work on this initial rollout and look forward to introducing the solutions developed to the wider SME community in the coming months.’

‘We are at a very deliberate inflection point in our growth journey where we have to challenge every process and every piece of work we are engaged in and find ways to improve efficiency and productivity so that we can compete in new markets against established manufacturers. No function or department is exempt, and we need to explore technologies to remove duplication of effort and streamline processes in our supply chain.’

Complete list of participants

Dyer Engineering is a group of fabrication and machining businesses manufacturing metal components and structures. They also provide maintenance, repair and overhaul support services, operating across a diverse range of markets, working with various metals, with the ability to process small parts which can be picked up by the handful, through to large-scale structures operating in harsh environments.

IINOUIIO are the only UK textile recycler of its kind. They are dedicated to recycling wool waste into beautiful new fibres, yarns and fabrics, which can then start a new life.

LaundRE is the UK’s first sustainable denim refinishing hub. They enable brands and retailers to reprocess unsold denim and dead stocks by changing the finish and shade with our laser and ozone technology. The refinished jeans are renewed and ready for full price resale.

Mackle Food company is a partner of choice for the innovation and manufacture of premium best in class innovative snacks.

McColgans are masters in savoury pastry, with 83 years of experience in the industry.

Ubloquity is transforming the UK’s ability to trade, by operationalising blockchain technology across global supply chains.

AgrigateOne does real-time tracking, smart document generation, unified data, dynamic reporting, precise forecasting, and effortless integration.

Kavida is a post-order management system that de-risks procurement by providing complete visibility of inventory in motion including real-time container tracking, early detection of risks to enable on-time supplier deliveries.

Flowlens is a cloud based software system for high tech SMEs who manufacture equipment devices or machinery. Flowlens helps these SMEs scale faster whilst staying in control of their data, orders, stock, suppliers and costs, removing the manual, repetitive and error prone admin enabling manufacturers to be more productive with fewer human resources.

Reverse Resources is an SaaS platform disrupting the fashion industry by connecting textile waste with recyclers.

Denchi Group offers a wide range of battery solutions for different sectors, including defence, medical, and industrial applications.