Warwick Manufacturing Group worked with sponsors Zoll Medical on defining a definition and framework to understand supply chain resilience as part of the Made Smarter Innovation | Digital Supply Chain Hub programme.

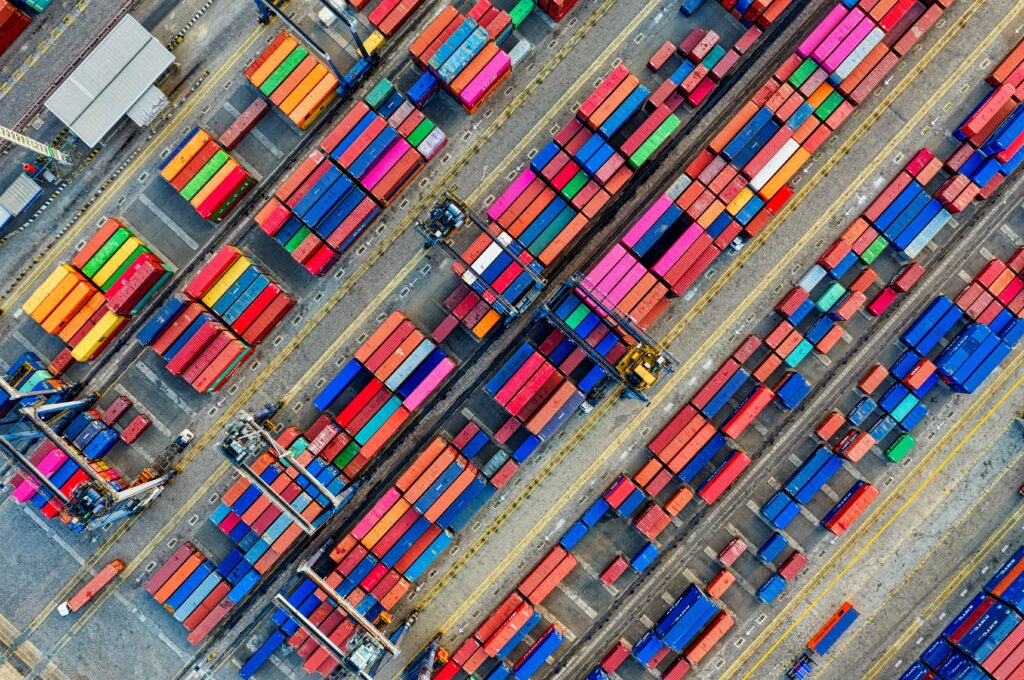

Supply chain resilience refers to the ability of a supply chain to withstand and quickly recover from disruptive events, such as natural disasters, pandemics, geopolitical conflicts, or supplier bankruptcies, that may negatively impact its operations and performance. A resilient supply chain is characterised by its ability to anticipate, absorb, adapt, and respond to unexpected disruptions, by minimising their impact on the flow of goods, services, and information, and by maintaining a high level of service quality, efficiency, and customer satisfaction. Achieving supply chain resilience requires a holistic and proactive approach that involves managing risks, building redundancy, flexibility, and agility, fostering collaboration and communication, and continuously monitoring and improving performance metrics.

Measuring supply chain resilience can be challenging, as it involves multiple dimensions and variables that may vary across different industries, geographies, and organisations. However, some commonly used metrics and approaches for measuring supply chain resilience include:

- Lead time variability: the degree of variation in the time it takes to complete a particular process or operation within the supply chain. High variability may indicate a lack of visibility or coordination among the supply chain partners, increasing the risk of disruptions.

- Inventory turnover: the rate at which inventory is sold and replenished within the supply chain. High inventory turnover may indicate a lean and efficient supply chain, but it may also lead to stockouts and increased vulnerability to demand fluctuations.

- Time-to-recovery: the time it takes to recover from a disruption and return to normal operations. Shorter time-to-recovery indicates a more resilient supply chain that can quickly adapt to changes and minimise the impact of disruptions.

- Financial performance: the financial stability and profitability of the supply chain partners. Financially stable partners are less likely to suffer from bankruptcy or other financial disruptions.

- Risk assessment: the identification and assessment of potential risks and vulnerabilities within the supply chain, such as single-source dependencies, geographic concentration, or inadequate contingency planning. A robust risk assessment can help prevent or mitigate the impact of disruptions.

- Customer satisfaction: the level of satisfaction and loyalty of the customers served by the supply chain. A resilient supply chain should be able to maintain high levels of customer satisfaction, even during disruptive events.

Find out about the work that WMG carried out as part of this project with the Made Smarter Innovation | Digital Supply Chain Hub and all the other projects here.